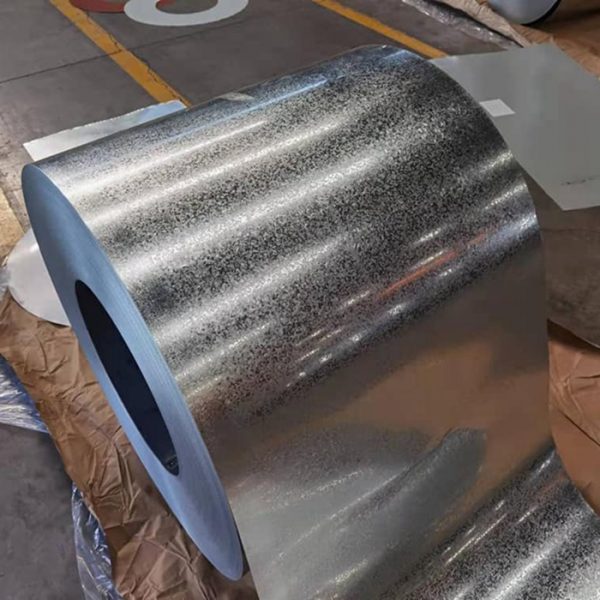

GI Steel Coil from Factory

GI steel coil details

A hot dip galvanized steel coil is immersed in a molten zinc bath to adhere galvanized steel to the surface. It is mainly produced by the continuous galvanizing process, that is, the coil is immersed in the galvanizing tank continuously to form galvanized steel plate; Alloy galvanized steel plate is used. This steel plate is also produced by hot dip plating, but it is heated to about 500℃ immediately after coming out of the oven to form zinc- iron alloy coating. This GI steel coil has good coating adhesion and weldability.

Regular spangle zinc coating |

In the normal solidification process of the zinc layer, the zinc crystal grains are freely grown to form a coating having a distinct zinc flower morphology. |

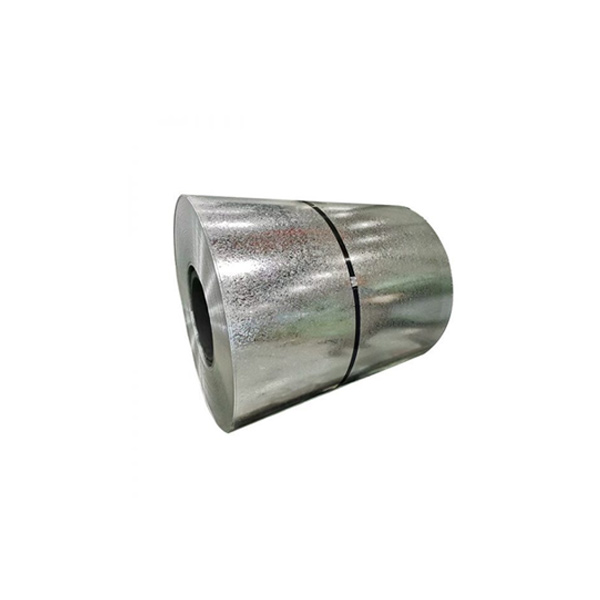

small spangle zinc coating |

During the solidification of the zinc layer, the zinc grains are artificially restricted to form as fine a zinc coating as possible. |

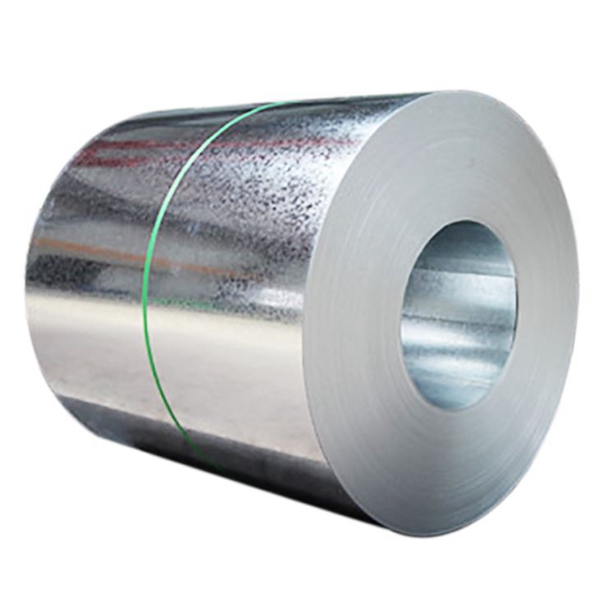

Zero-spangle zinc coating |

By adjusting the chemical composition of the plating solution, there is no visible zinc flower morphology, and the surface is uniformly coated. |

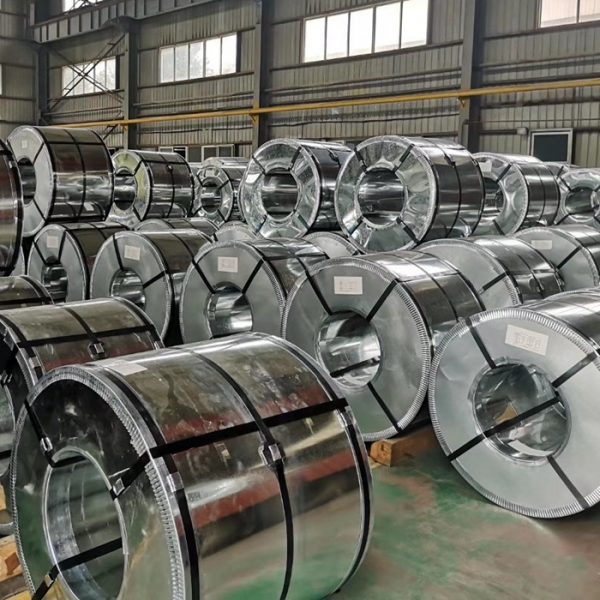

2. GI Steel Coil production process

GI Steel Coil is produced through a metal-coated process that involves passing cold-rolled coils through a cauldron filled with molten zinc. This process ensures zinc adhesion to the surface of the steel plate. Zinc coating provides excellent corrosion resistance and extended service life.

3. Packing Detail

Packing: kraft paper in the inner layer, a hydroplastic film in the middle, GI steel plate in the outer layer, covered with a locking steel belt, and a diameter sleeve in the inner ring.

Step One: Packed with moisture-proof kraft paper

Step Two: Wrapped with iron sheets fixed by steel strips

Step Three: Loading into a container and delivery to port

Inquiry

If you would like to contact us for more information about our products,

please fill out the form below, thank you.