Commodity |

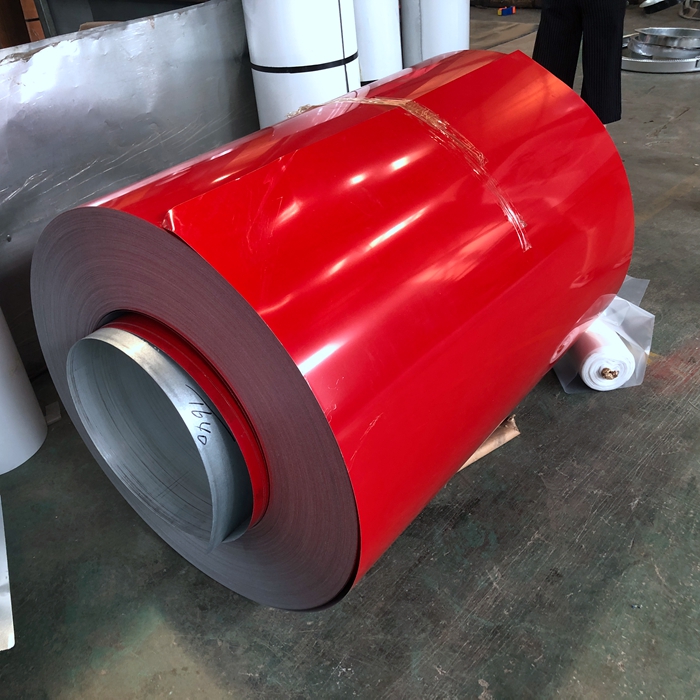

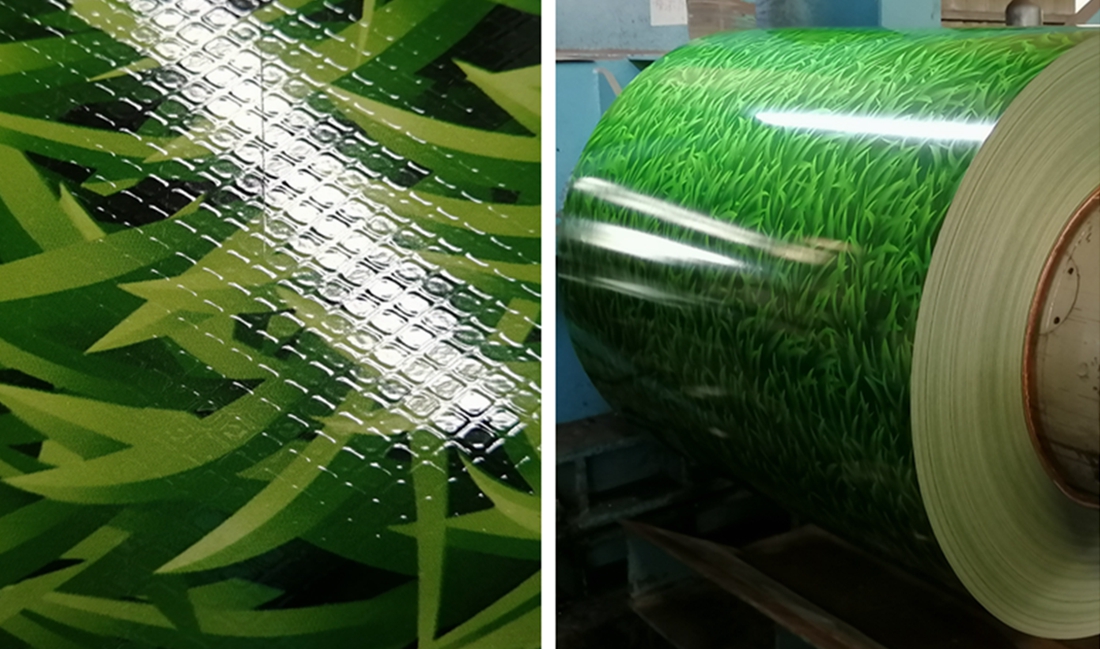

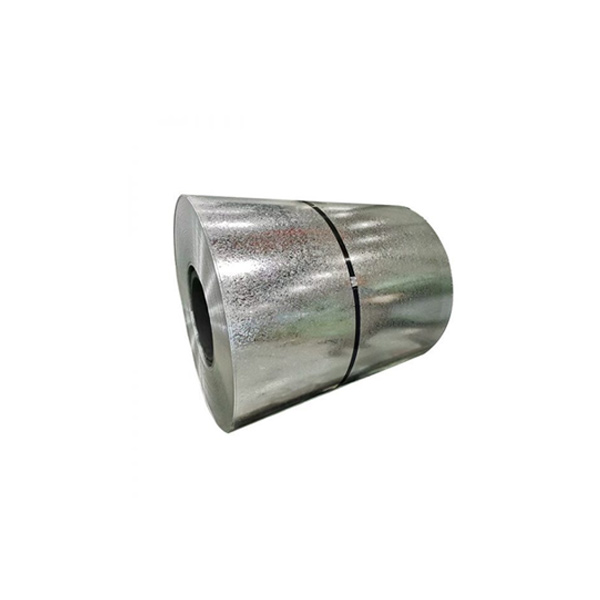

PPGI Steel Coil |

Standard |

GBT2518-2008 , ASTM A653 , JIS G3302-1998 , EN 10142-2000 |

Grade |

SGCC ,DX51D+Z ,DX52D+Z ,DX53D+Z ,DX54D+Z ,Q195 ,Q235 ,Q345 |

Thickness |

0.1mm-2.0mm |

Width |

600mm-1500mm |

Length |

According to customer requirements |

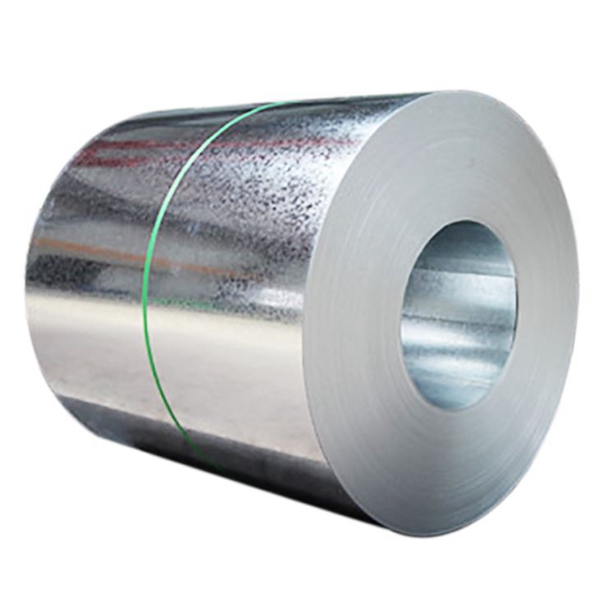

Zinc coating |

Z60-Z275g/m2, according to customers’ requests |

SurfaceTreatment |

chromed, skin pass, oiled, unoiled, slightly oiled, dry |

Trade Terms |

CIF, CFR, FOB |

Payment Term |

30% Advance Payment+70% balance payment before shipping T/T,100% L/C at sight |

Advantage |

Excellent price, competitive price, prompt delivery |

Package |

Standard export seaworthy package, such as : bare packing, bundle packing, wooden carton packing |

Quality control |

Mill Test Certification is supplied with shipment, Third Part Inspection is acceptable. |

Export to |

Singapore, Indonesia, Ukraine, Saudi Arabia, Turkey, Bangladesh, South Africa, Chile, Brazil, Thailand, South Korea, India, Egypt, Oman, Malaysia, Kuwait, Vietnam, Pakistan, Peru, Mexico, Panama, Dubai, Russia, etc. |

Application |

Mainly used in Construction, machinery manufacturing, iron and steel construction projects, shipbuilding, solar power support, steel structure engineering, power engineering, power plant, agriculture and chemical machinery, glass curtain wall, automobile chassis, airport, etc. |

Container size |

20ft GP:5898mm(Length) x 2352mm(Width) x 2393mm(High) 24-26CBM40ft GP:12032mm(Length) x 2352mm(Width) x 2393mm(High) 54CBM40ft HC:12032mm(Length) x 2352mm(Width) x 2698mm(High) 68CBM |

Supply capacity |

3000Ton/Month |

Basic features of PPGI Steel Coil

1. Lightweight: 10-14 kg/square meter, equivalent to 1/30 of the brick wall.

2. high strength: can be used as a ceiling, bending, compression bearing structure; Ordinary houses do not use beams and columns.

3. bright color: no surface decoration, color galvanized steel coating anticorrosive layer to maintain for 10-15 years.

4. flexible and fast installation: can shorten the construction period by more than 40%.

5. oxygen index :(OI) 32.0 (provincial fire products quality inspection station).

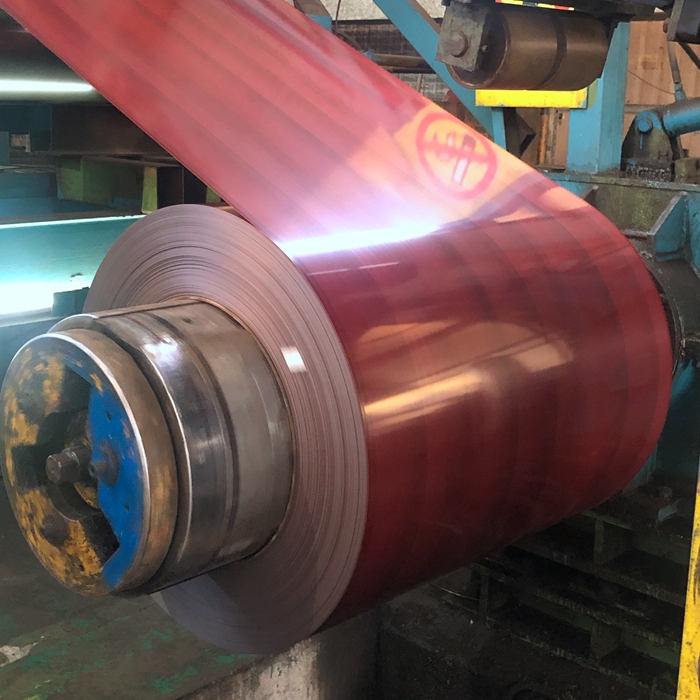

PPGI Steel Coil Main Production Process

The crane is used to place the raw material coil on the processing platform of the color coating unit, and the transporter transports the steel coil to the coil seat in front of the color coating unit. Remove the tape after the raw material is into the cooler, conduction band device will automatically lead to the column header cutting head of cutting position, and then the sewing machine will take girth into the cleaning area, first will wash and volume Then by drying, into the chemical plating machine, in the watercolor coated steel coil surface coated with a layer of chromium, hot air drying machine into the drying machine from the chemical plating, The coating is then thinly coated on the steering roller into the coater fine, and then the coating is dried into the curing oven.

Package & Shipping

Package for PPGI Steel Coil |

|

Generally package |

waterproofing paper+strapped with min three strapping strips |

Standard exporting package |

waterproof paper and plastic+covered by iron sheet+ strapped with minthree strapping strips |

Excellent package |

waterproof paper and plastic film+ covered by iron sheet+ strapped withmin three strapping strips+fixed on the iron or wooden pallets by strappingstrips. |